High performance additive manufacturing.

Partner of your projects, from development to manufactured part.

MMB VOLUM-e uses extremely rigorous design and manufacturing methods allowing to obtain high performance parts for high-tech industries in all prototyping and additive manufacturing techniques : Aeronautics, Aerospace, Defense, Mobility, Medical, Energy …

To strengthen its value chain and create serial production capabilities, MMB VOLUM-e announces that is has signed a close cooperation agreement with the Lincotek group located in Parma (Italy) – Global expert in special additive manufacturing processes and coatings.

COMPETENCES METIERS

- Additive Manufacturing

METAL / Max size : 400x400x360mm

- 1 EOS M280

- 5 EOS M290

- 3 EOS M400, dont une 4 lasers

- 1 Realizer SLM100

- 1 Realizer SLM50

PLASTIQUE

- Stereolithography :

9 machines at max volume of 750x650x550mm

- Powder sintering :

3 machines at max volume of 505x505x440mm or 330x330x600mm

- 1 EDM

- Machining

7 machining centers 3 and 5 axes for milling soft or hard materials. Max size : 4500x1800x1400mm

- Vacuum casting

6 production machines with max size of 3000x1000x800mm

CERTIFICATIONS & CHIFFRES CLES

A complete and controlled value chain

* Conception, fabricability, production, 3D control

- 50 employees – 39 machines

- 1 Design Office & 1 Methods Office

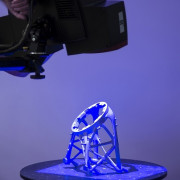

- Control with 3D Scanner, 1 3D measuring machine

- 1 Quality Office

- 1 Materials laboratory

- 1 Modeling service

- High finishes : paint, metallization et surface treatment

- Large size production capacity : 400x400x360mm

- Premium model, prototyping, unique part, limited edition and small serie

MMB VOLUM-e

MMB VOLUM-e

1 chemin de la fonderie

F-76340 Blangy-sur-Bresle

Phone : +33 2 32 97 53 20

www.mmbvolum-e.com